Prints, Fabrics & Seams

Print Options

At Precision Backdrops, we offer three different print options for our backings, day|night, day and midnight.

Day|Night Backings

Certainly our most popular option, Day|Night backings offer both front and backing lighting abilities allowing for the most versatility on set. Front lighting produces a daytime look whereas back lighting produces a late dusk to night look.

Day Backings

If you only need a day time view or are on a tight deadline, choose our day backings, which are designed to be front lit only. Without the need to capture, create and print the night image, the photography, retouching and production all allow for faster turn around times. Likewise, production costs tend to be lower, allowing for a more budget friendly option.

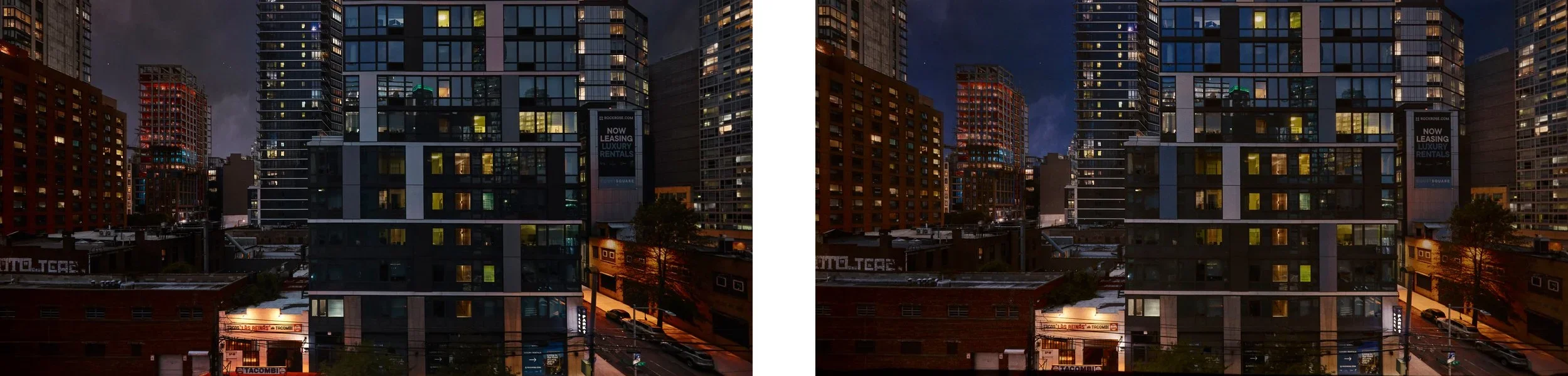

Midnight Backings

Utilizing an unique printing process, our midnight backings produce a true midnight look. When back lit, these backings produce vibrant and saturated highlights along with blacks and shadows that do not wash out. Likewise, unlike with day|night backings where the brighter blue sky on the day image makes it difficult to achieve a true night look, the skies in our midnight backings remains strikingly dark even with substantial back lighting. Production costs and time frames for our midnight backings are similar to our day|night backings.

Ink & Color Saturation

At Precision Backdrops, we utilize and offer two different printing and ink management software, allowing for different saturation levels in the final backdrop. Below are the options we offer along with descriptions and comparisons of photographs of actually backings.

Opal

Our Opal setting uses less ink and creates a muted color space. The backdrop will be about 20% less saturated then it would be with Sapphire. Given the smaller amount of ink used, the sheen will be less and between matte and eggshell. DMax is noticeably lower, leading to subdued blacks and brighter backlighting.

Sapphire

Our Sapphire setting uses the most ink, allowing for a backdrop that is as saturated as the digital file. This is our default setting and what we use if no guidance is given. Given the amount of ink used, the sheen is roughly eggshell. Likewise, DMax will be greater with deeper blacks and shadows.

Fabric

Unless otherwise requested, all of our backings are printed on a 9 oz per square yard polyester fabric that is specifically designed for both front and back lighting purposes.

Unlike vinyl, our fabric is foldable and lighter in weight, allowing for easier rigging, shipping and storage.

Additionally, our fabric’s thicker denier, tighter weave and coatings easily allows lighting technicians to avoid hot spots and eliminate pinholes when back lighting, especially compared to thinner natural fabrics. Our fabric is inherently resistant to rot, mold and water damage and fire, and can be easily cleaned on site of most organic stains.

Seams

Our fabric maxes out at 16 feet, like all other commercially available fabrics. For any backdrops taller then 16 feet, we will need to seam multiple vertical panels to produce the final drop. In the world of backdrops, the seaming could arguably be the most important aspect of production.

Through a year long experimentation, we have develop a proprietary multi-step seaming process that creates strong seams that are invisible on screen. Utilizing custom manufactured supplies only available to us, our seams employs two mechanical bonds between each panel that eliminates the possibility of any hairline separation from forming either during the process or from normal wear and tear.

Although we are proud of our seaming process, this is as much information we can share publicly. We are happy to discuss it further on the phone to alleviate any concerns.